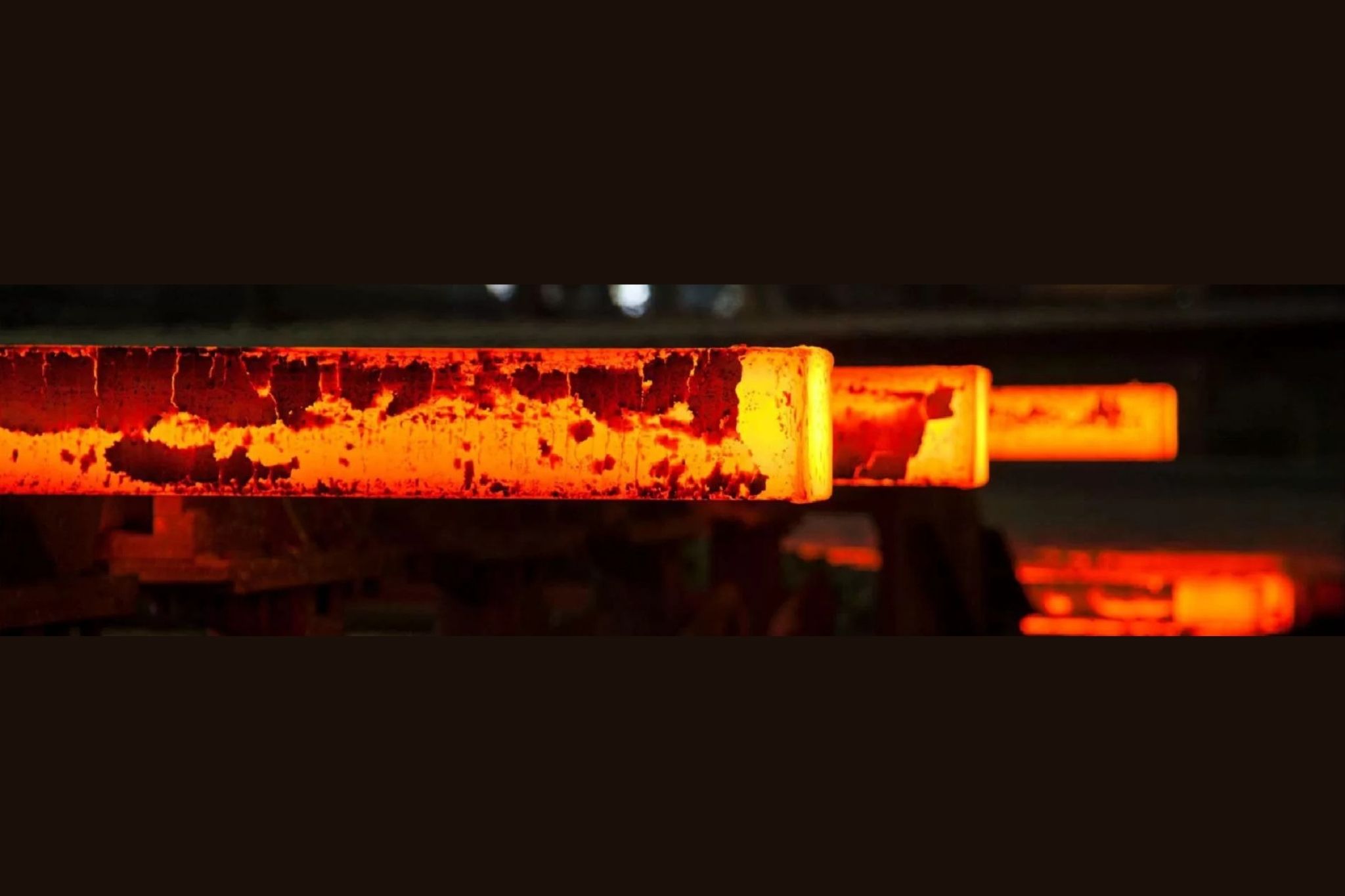

Hot Work Tool Steels

Hot Work Tool Steels

Hot work tool steels are specialized steel types designed for applications that involve high temperatures and intensive thermal processing. These steels possess exceptional properties such as high temperature resistance, thermal shock resistance, wear resistance, and toughness. Hot work tool steels resist thermal expansion and contraction, maintaining their strength even at high temperatures.

Where Are Hot Work Tool Steels Used?

Hot work tool steels are used in various industrial applications. Their main areas of use include:

- Metal Forming: Hot forging molds, hot extrusion molds, and hot forming tools.

- Die Casting: Casting molds used in the processing of metals such as aluminum, magnesium, and zinc.

- Hot Cutting: Cutting blades and shears that operate at high temperatures.

- Press Casting: Metal injection molds and pressure casting molds.

- Extrusion: High-temperature metal and alloy extrusion molds.

These types of steels are specifically designed to provide high performance under demanding working conditions, offering long-lasting and reliable solutions in the industry.

Specified Hot Work Tool Steels

SC 1.2344

- DIN: X40CrMoV5-1

- Properties: High temperature resistance, good toughness, excellent thermal shock resistance

- Applications: Aluminum, magnesium, and zinc die casting molds, hot cutting blades, extrusion molds

SC 1.2343

- DIN: X37CrMoV5-1

- Properties: High temperature resistance, good toughness, thermal shock resistance

- Applications: Hot forging molds, press casting molds, hot cutting applications

SC 1.2714

- DIN: 55NiCrMoV7

- Properties: High impact resistance, good toughness

- Applications: Heavy forging molds, large cutting tools, pressure casting molds

SC 1.2367

- DIN: X38CrMoV5-3

- Properties: High temperature resistance, excellent wear resistance, good thermal shock resistance

- Applications: Hot forging molds, extrusion molds, high temperature applications

Hot Work Tool Steels Features

| Steel Type | Features | Application Area |

|---|---|---|

| SC 1.2344 | – DIN: X40CrMoV5-1<br>- High temperature resistance<br>- Good toughness<br>- Excellent thermal shock resistance | Aluminum, magnesium, and zinc die casting molds, hot cutting blades, extrusion molds |

| SC 1.2343 | – DIN: X37CrMoV5-1<br>- High temperature resistance<br>- Good toughness<br>- Thermal shock resistance | Hot forging molds, press casting molds, hot cutting applications |

| SC 1.2714 | – DIN: 55NiCrMoV7<br>- High impact resistance<br>- Good toughness | Heavy forging molds, large cutting tools, pressure casting molds |

| SC 1.2367 | – DIN: X38CrMoV5-3<br>- High temperature resistance<br>- Excellent wear resistance<br>- Good thermal shock resistance | Hot forging molds, extrusion molds, high temperature applications |

These steel types are preferred for their ability to withstand high-temperature working conditions and provide long-lasting performance.