Aluminum Alloys

Aluminum Alloys

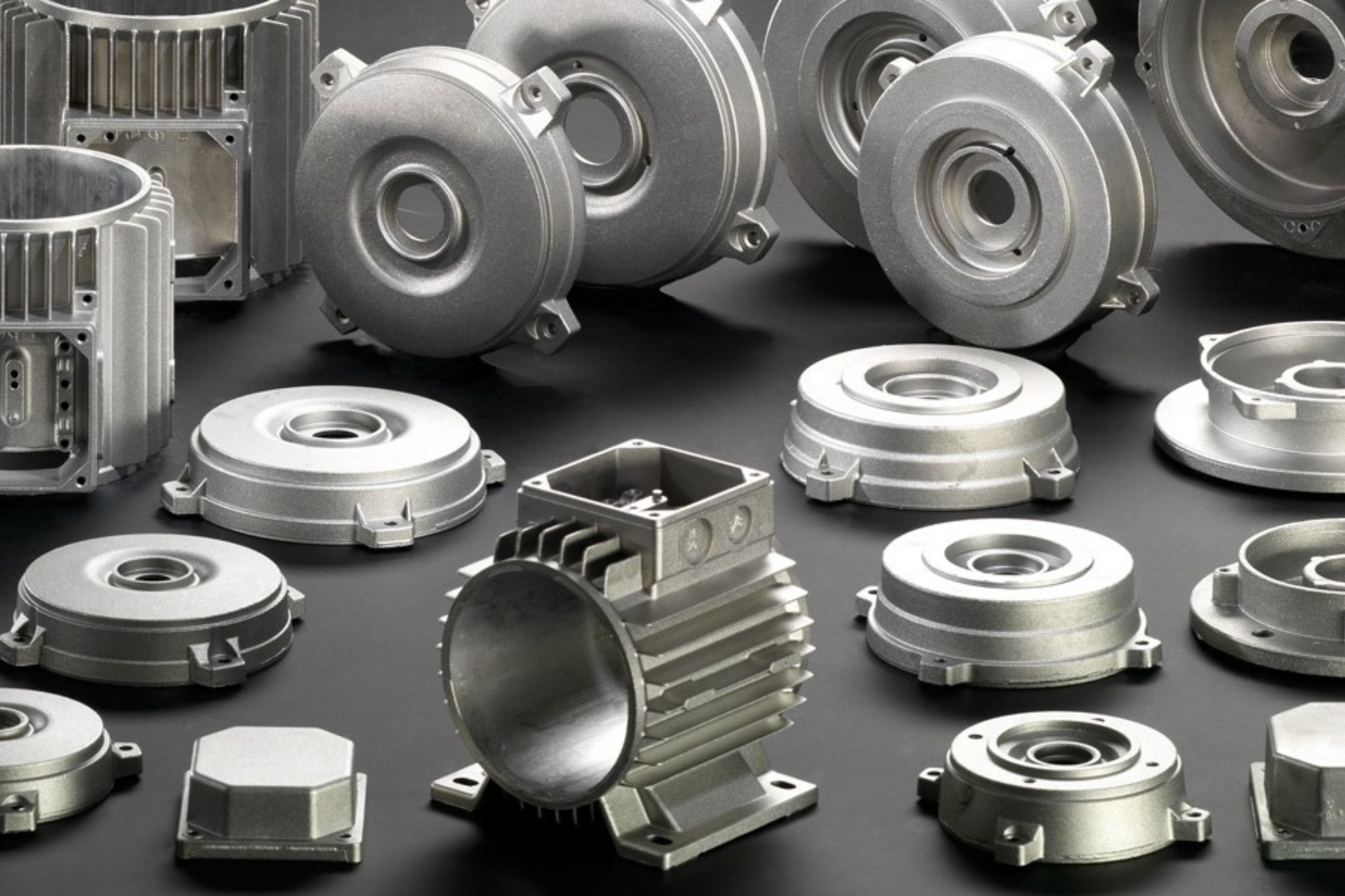

Aluminum alloys are metal materials widely used in many industries due to their lightness, durability, and workability. Pure aluminum may not be strong enough, so it is alloyed with various elements to enhance performance characteristics. Understanding the general types and applications of aluminum alloys can help you better understand how these alloys are used in various sectors.

What Are Aluminum Alloys?

Aluminum alloys are metal mixtures created by adding other elements to pure aluminum. These alloys improve the properties of aluminum and make it suitable for specific applications.

Types of Aluminum Alloys

Aluminum alloys are generally divided into two main categories: Aluminum-Silicon Alloys (Al-Si) and Aluminum-Copper Alloys (Al-Cu). Both categories include different types of alloys and are used in various applications.

-

Aluminum-Silicon Alloys (Al-Si)

What Are Aluminum-Silicon Alloys?

Aluminum-silicon alloys are mixtures of aluminum and silicon elements, commonly used in automotive and casting applications. Silicon imparts hardness and high-temperature resistance to the alloys.

Where Are Aluminum-Silicon Alloys Used?

- Automotive Industry: Engine blocks, cylinder heads, and casting parts.

- Aerospace: Lightweight and high-performance components.

- Electrical Equipment: Conductors, transformers, and electric motors.

- Construction and Building: Facade claddings, window frames, and various building components.

Types of Aluminum-Silicon Alloys

Alloy Code Description AlSi10Mg Casting alloy with high durability and workability. AlSi12 Provides high fluidity and ease of casting. AlSi7Mg Offers good corrosion resistance and high strength. -

Aluminum-Copper Alloys (Al-Cu)

What Are Aluminum-Copper Alloys?

Aluminum-copper alloys are mixtures of aluminum and copper elements. These alloys generally offer high strength and hardness characteristics.

Where Are Aluminum-Copper Alloys Used?

- Aircraft and Aerospace: High-strength and lightweight structural elements.

- Construction Industry: Load-bearing frames, support systems.

- Automotive: Lightweight yet robust structural components.

- Industrial Equipment: Machine parts, applications requiring high durability.

Types of Aluminum-Copper Alloys

Alloy Code Description Al2024 High-strength alloy, commonly used in aircraft structures. Al7075 Provides high durability and hardness. Al6061 Offers good corrosion resistance and workability.

General Applications of Aluminum Alloys

| Alloy Type | Applications |

|---|---|

| Al-Si Alloys | Automotive parts, aerospace, electrical equipment, construction projects |

| Al-Cu Alloys | Aircraft structures, industrial applications, automotive components |

Advantages of Aluminum Alloys

| Advantages | Description |

|---|---|

| Lightness | Aluminum alloys are lightweight materials due to their low density. |

| Corrosion Resistance | Aluminum forms a natural oxide layer, providing protection against corrosion. |

| High Strength | Various alloys offer high strength and durability characteristics. |

| Workability | Easily machinable, weldable, and formable. |

| Good Heat Distribution | High thermal conductivity improves heat distribution. |

| Aesthetic Appearance | Provides a sleek and modern look, with various surface coatings for aesthetic solutions. |

General Types and Technical Specifications of Aluminum Alloys

| Alloy Type | Technical Specifications | Applications |

|---|---|---|

| AlSi10Mg | High durability, workability | Automotive engine blocks, aerospace, construction |

| AlSi12 | High fluidity, good casting properties | Casting parts, structural elements |

| AlSi7Mg | Good corrosion resistance, high strength | Facade cladding, automotive parts |

| Al2024 | High strength, low corrosion resistance | Aircraft structures, high-performance components |

| Al7075 | High durability, hardness | Aircraft structures, automotive, sports equipment |

| Al6061 | Good corrosion resistance, workability | Construction, industrial applications |

General Comparison of Aluminum Alloys

| Alloy Code | Features | Applications |

|---|---|---|

| AlSi10Mg | Durable, workable, good casting properties | Automotive engine blocks, aerospace |

| AlSi12 | Good fluidity, ideal for casting parts | Casting parts, structural elements |

| AlSi7Mg | High corrosion resistance, high strength | Facade cladding, automotive parts |

| Al2024 | High strength, low corrosion resistance | Aircraft structures, high-performance components |

| Al7075 | High durability, hardness | Aircraft structures, automotive, sports equipment |

| Al6061 | Good corrosion resistance, workability | Construction, industrial applications |

Aluminum Alloys Usage Areas and Technical Specifications

| Alloy Type | Technical Specifications | General Usage Areas |

|---|---|---|

| Al-Si Alloys | Lightweight, high fluidity, good corrosion resistance | Automotive, aerospace, electrical equipment |

| Al-Cu Alloys | High strength, hardness | Aircraft structures, industrial equipment |

Usage Areas of Aluminum Alloys

| Alloy Type | Usage Areas |

|---|---|

| Al-Si Alloys | Automotive engine blocks, aerospace, electrical equipment, facade claddings |

| Al-Cu Alloys | Aircraft structures, industrial applications, automotive parts |

Advantages and General Usage Areas of Aluminum Alloys

| Advantages | Description |

|---|---|

| Lightness | Known for their light weight as materials. |

| Corrosion Resistance | Forms a natural oxide layer for protection against corrosion. |

| High Strength | Various alloys provide high strength and durability. |

| Workability | Easily machinable, weldable, and formable. |

| Good Heat Distribution | High thermal conductivity improves heat distribution. |

| Aesthetic Appearance | Offers aesthetic solutions with sleek and modern appearances. |

Aluminum alloys are widely used materials due to their lightness, durability, and suitability for various industrial applications. Different alloys offer customized performance features for various applications.

This overview can help you understand what aluminum alloys are, how they are used, and the characteristics of different types.

Aluminum Alloys Properties Table

| Alloy Code | Technical Specifications | Usage Areas |

|---|---|---|

| AlSi10Mg | High durability, good workability | Automotive engine blocks, aerospace, construction |

| AlSi12 | High fluidity, good casting properties | Casting parts, structural elements |

| AlSi7Mg | Good corrosion resistance, high strength | Facade cladding, automotive parts |

| Al2024 | High strength, low corrosion resistance | Aircraft structures, high-performance components |

| Al7075 | High durability, hardness | Aircraft structures, automotive, sports equipment |

| Al6061 | Good corrosion resistance, workability | Construction, industrial applications |

Conclusion

Aluminum alloys have a wide range of applications due to their lightness, durability, and suitability for various industrial uses. Each type of alloy offers specific features and advantages tailored to different sector needs.